After years of running DN Contracting, one truth has stayed consistent across offices, retail centers, warehouses, and medical facilities. Commercial paint does not fail randomly. When cracking shows up early, the root cause is almost always poor surface preparation.

Commercial buildings in Aberdeen, MD place far more stress on paint systems than residential structures. Large wall spans move. HVAC systems cycle constantly. Moisture loads fluctuate daily. Foot traffic, equipment vibration, and cleaning chemicals all push against the coating. When surfaces are not properly cleaned, tested, repaired, dried, and primed, the paint film absorbs stress it was never designed to handle.

No coating can overcome poor surface preparation. Cracks simply appear sooner in commercial spaces because the environment exposes the weakness faster.

Key Takeaways

-

Poor surface preparation is the primary cause of early cracking in commercial paint systems

-

Commercial buildings experience higher movement, moisture, and operational stress

-

Cracks often signal adhesion failure or substrate instability

-

High-performance coatings cannot compensate for preparation shortcuts

-

Proper preparation protects budgets, uptime, and asset value

What Is Poor Surface Preparation in commercial painting?

How Surface Preparation Differs in Commercial Environments

In commercial painting, preparation is not just washing walls and applying primer. Commercial spaces are larger, more complex, and often occupied during work. Surfaces vary from drywall and CMU to steel, concrete, and specialty finishes. Each substrate requires a different preparation strategy.

In Aberdeen, MD, many commercial buildings also face coastal humidity and seasonal temperature swings, which further reduce the margin for error.

The Technical Components of Proper Commercial Preparation

Proper preparation includes contaminant removal, moisture testing, surface repairs, profiling where required, and correct priming. Each step supports adhesion and flexibility. Skipping even one leads directly to poor surface preparation and early cracking.

Why Commercial Buildings Are Less Forgiving of Prep Errors

Commercial structures move more, operate longer hours, and face constant use. When preparation is rushed, the paint film becomes the stress absorber instead of the substrate. That stress shows up as cracks.

Why Poor Surface Preparation Causes Commercial Paint to Crack Fast

Paint Film Stress on Large Commercial Surfaces

Large wall expanses expand and contract with temperature changes. Without proper surface bonding, the coating cannot flex. Cracks form along predictable stress lines.

Adhesion Failure Under Operational Conditions

HVAC cycling, elevators, mechanical rooms, and daily foot traffic introduce vibration. In commercial painting, these forces quickly expose weak adhesion caused by poor surface preparation.

Why Cracks Appear Before Peeling or Delamination

Cracking is often the first visible sign of failure. It indicates internal stress has exceeded adhesion strength, even if the coating has not yet separated.

Most Common Commercial Poor Surface Preparation Errors

Inadequate Cleaning of High-Traffic Areas

Dust, grease, and airborne contaminants accumulate quickly in commercial spaces. Painting over them prevents mechanical bonding and leads to cracking under normal use.

Painting Over Moisture-Affected Surfaces

Bathrooms, kitchens, basements, and mechanical rooms frequently hold residual moisture. When not tested and dried properly, moisture pressure cracks the coating from below.

Ignoring Existing Cracks, Joints, and Failed Coatings

Stress concentrates along joints and previous failures. Covering them without repair guarantees cracks will reappear.

Moisture-Related Poor Surface Preparation Failures in Commercial Buildings

Painting Without Moisture Testing

Moisture trapped beneath coatings creates vapor pressure. As temperatures rise, pressure forces the paint film to crack.

Poor Sealing at Penetrations and Expansion Joints

Pipes, conduit, and movement joints allow moisture intrusion. Without proper sealing, coatings fail at these weak points.

Why Commercial Interiors Trap Moisture Longer

Limited ventilation and continuous operation prevent proper drying, making poor surface preparation more common.

Substrate-Specific Preparation Errors in Commercial Properties

Substrate-Specific Preparation Errors in Commercial Properties

Drywall and Partition Wall Failures

Fast-track construction often leaves joint compounds under-cured. Without stabilization and priming, seam cracking occurs quickly.

Concrete and CMU Preparation Mistakes

Concrete surfaces contain laitance and alkalinity. Without profiling and neutralization, coatings lose adhesion and crack.

Metal Surface Preparation Errors

Rust, mill scale, and smooth steel surfaces require mechanical profiling. Painting over them causes early failure.

Primer and Coating System Errors That Lead to Cracking

Skipping Primer to Save Time or Money

Primer stabilizes porous surfaces and promotes adhesion. Skipping it creates uneven stress distribution.

Using Residential Products in Commercial Spaces

Residential primers lack the durability required for commercial painting environments.

Incorrect Recoat Windows

Applying coatings outside recommended windows traps solvents and increases internal stress.

Interior vs Exterior Commercial Paint Cracks

Interior Cracks in Offices, Retail, and Healthcare

Interior cracks often follow vibration paths from HVAC systems and foot traffic.

Exterior Cracks on Commercial Facades

UV exposure, weather, and building movement stress coatings constantly.

Why Exterior Preparation Errors Cost More

Access equipment, safety planning, and tenant disruption increase repair costs significantly.

Why High-Performance Commercial Paint Still Fails Without Preparation

The Limits of Elastomeric Coatings

Crack-bridging products still rely on adhesion. They cannot overcome poor surface preparation.

Manufacturer Warranty Requirements

Most warranties require documented compliance with Surface Preparation Standards. Failure to follow them voids coverage.

Financial Impact of poor surface preparation in commercial painting

Reduced Coating Lifespan

Early cracking shortens repaint cycles and increases lifecycle costs.

Business Disruption and Downtime

Repainting occupied spaces interrupts operations and affects tenants.

Long-Term Asset Devaluation

Visible paint failure reduces perceived property value and increases maintenance risk.

How Professional Commercial Painters Prevent Cracking

Pre-Project Surface Assessment

At DN Contracting, we test moisture, assess adhesion risk, and document surface conditions before work begins.

Proper Surface Repair and Stabilization

Cracks are treated, joints reinforced, and substrates conditioned before coating.

System-Based Coating Selection

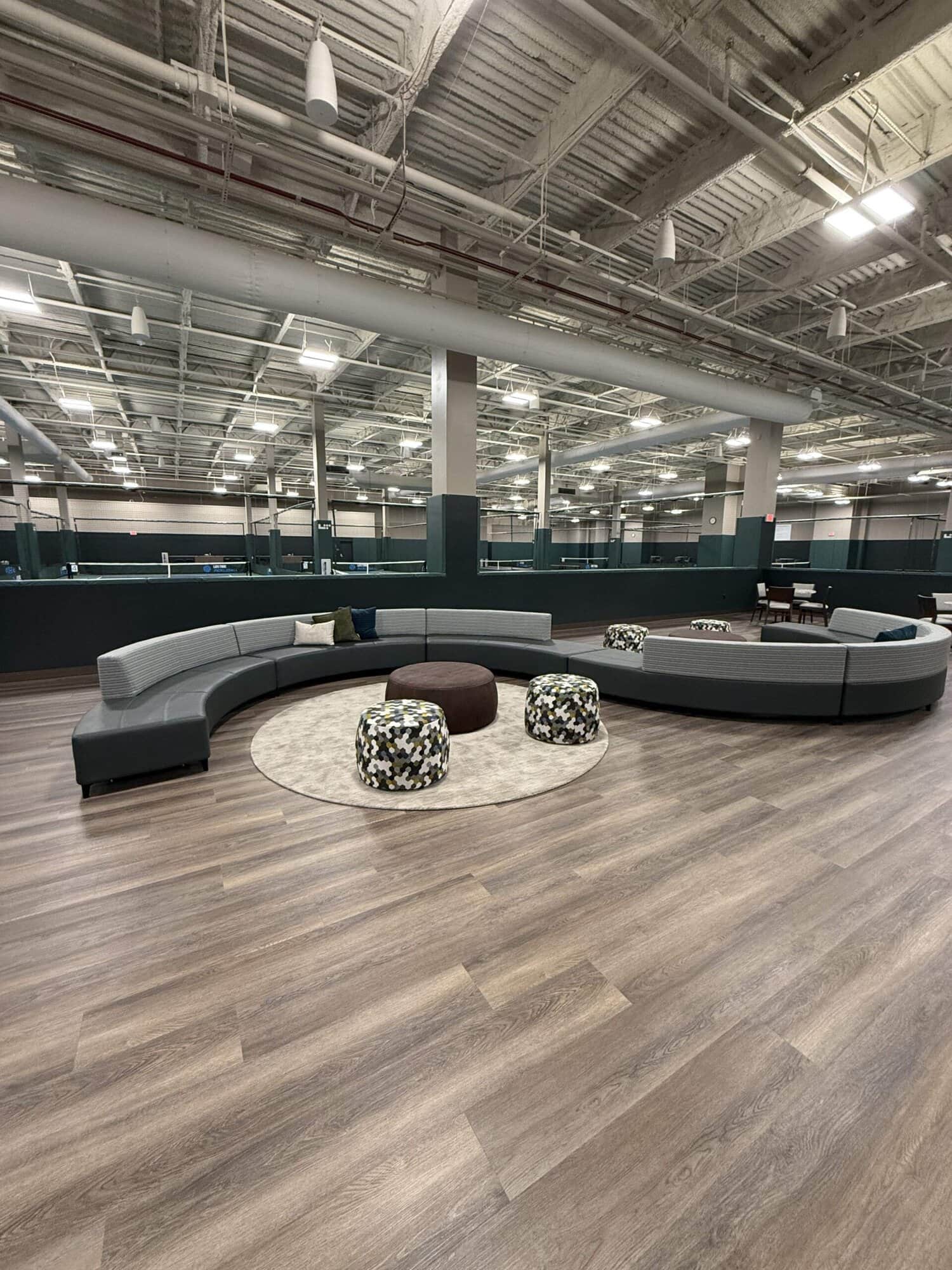

We match primers and finishes to the substrate and environment, including areas with decorative floor coatings where surface prep is especially critical.

Warning Signs Commercial Cracks Are Prep-Related

Cracks Appearing Within 30 to 120 Days

This timeline strongly indicates poor surface preparation.

Cracks Following Structural Lines

Movement mapping reveals where preparation failed.

Clean Separation from the Substrate

Clean breaks confirm adhesion failure.

How to Correct Commercial Paint Cracks Caused by poor surface preparation

When Spot Repairs Are Not Enough

Systemic failure requires full removal and re-preparation.

Proper Removal and Re-Preparation

Defective coatings must be stripped, surfaces stabilized, and systems rebuilt correctly.

Planning Repairs to Minimize Disruption

Phased work allows businesses in Aberdeen, MD to remain operational.

How Facility Managers Can Avoid poor surface preparation

What to Require in Painting Specifications

Require documented prep steps, testing, and compliance with Surface Preparation Standards.

Questions to Ask commercial painting Contractors

Ask how surfaces are tested, repaired, and verified before coating.

Why Lowest-Bid Prep Scopes Fail

Cutting preparation always increases long-term costs.

Commercial Paint Cracks Are a Preparation Failure

Commercial paint cracking is not a mystery. It is a predictable outcome of poor surface preparation. In commercial painting projects throughout Aberdeen, MD, durable coatings are built on disciplined preparation, not shortcuts.

At DN Contracting, we have learned that preparation is not an expense. It is protection for your building, your operations, and your investment.

Substrate-Specific Preparation Errors in Commercial Properties

Substrate-Specific Preparation Errors in Commercial Properties